EU harmonised standards improve safety of lifts, reduce costs and facilitate trade

—Interview with Mr Esfandiar Gharibaan, Chairman of CEN/TC 10 and Vice President of Codes and Standards in KONE Corporation

欧洲协调标准能有力提高电梯安全性、降低成本并促进贸易

——访CEN/TC 10主席、通力电梯法规与标准副总裁 埃斯凡迪亚尔·加里班

Based on your years of international work experience, what are the main developmental trends of the global lift and escalator industry in the coming years?

Esfandiar Gharibaan: Safety remains the most important topic of standardization. We continuously revise our standards to reflect the state of the art in safety for design and operations. Sustainability is another key focus point. In the past, for lifts and escalators, our focus has been on energy efficiency, and we have a set of international standards (EN ISO 25745-1/2/3) for this. However, international as well as national standardization organisations are developing many standards which address the life cycle of the products. Those standards may not directly cover lifts and escalators, but they will certainly have influence on these products. While we, as the lift industry, are following and participating in developing those standards, we are also considering whether specific standards may need to be developed on the subject of sustainability for lifts and escalators.

As more and more lifts and escalators are being connected to the Internet and other networks, another important topic is digitalization, and more specifically, connectivity. There has been a giant lip in the standardization for Internet-of-Things (IoT) and Machine-to-Machine (M2M) connectivity in general. Those standards affect lifts and escalators as well, but considering the specificities of lifts and escalators products, we need specific standards, at least for some aspects of the connectivity for these products. A good example is cybersecurity. And I am happy to see that ISO 8102-20 has been published recently. We may extend the work to other aspects as the needs are being identified and the technologies are maturing.

There have been extensive efforts to align, converge and harmonise requirements for lifts and escalators as defined by the national standards. This technical harmonisation among countries around the world greatly facilitates circulation of safe products and improves trade among those countries. ISO standards, when adopted by each country, provide an ideal means for such harmonisation. We see that more and more standards are developed at the ISO level with much input and contribution from the ISO members. It is important to note that there is a close cooperation between CEN and ISO and many of the standards from one organisation are adopted by the other and there are several joint projects on-going.

In view of these developmental trends, what are the plans and tasks of CEN/TC 10 today and in the future?

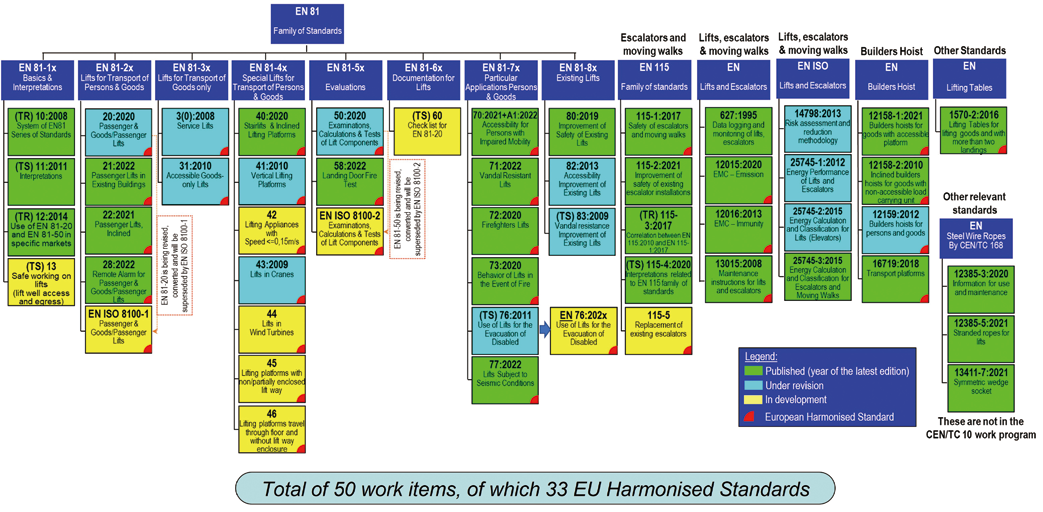

CEN/TC 10 has developed many standards (see Figure 1) which are being used internationally. The immediate task is to revise and update those standards in line with the latest technological and regulatory changes.

Technical harmonisation remains a key objective. We are working closely with ISO/TC 178 to make sure that the new items for standardization are developed as the global standards and avoid parallel or repetitive work in CEN or ISO. This is especially important for the digitalization and connectivity standards, where other markets, in particular China, are much more experienced than the European market and we can benefit from that experience.

We are also considering moving several EN standards, such as EN 81-70, to become global ISO standards.

We closely follow the regulatory and standardization activities on the topic of sustainability and in cooperation with the industry associations determining the relevance and impact for the lift industry and decide on the new work items in the future.

Which new standards can be expected soon? What key role will they play in the industry?

The current work program of CEN/TC 10 is shown in the Figure 1.

Figure 1: CEN/TC 10 work program

New standards under development are:

New standards will provide a solid basis for the technical harmonisation for lifts (EN ISO 8100-1/2) and will be a huge opportunity to improve efficiency of the industry. New standards also provide guidance in application of the EN standards (CEN/TS 81-13 and CEN/TS 81-60) as well as improving safety (EN 81-42, 44, 45, 46 and EN 115-5) and for the first time we will provide a standard for lifts used for the evacuation of buildings (EN 81-76).

What is EU Harmonised Standard? And which standards developed by CEN/TC 10 have been and will be recognized as EU Harmonised Standards? As Chairman of CEN/TC 10, how do you collaborate with the EU in this harmonisation process?

In the EU regulatory framework, the requirements in the technical regulations define the safety objectives to be reached. However, those regulations do not describe the technical specification to achieve those safety objectives. EU Harmonised Standards provide the necessary technical specifications to fulfill the safety objectives of the regulation.

EU Harmonised Standards are developed by the European Standardization Organisations, CEN, CENELEC (European Committee for Electrotechnical Standardization) and ETSI (European Telecommunications Standards Institute). Those standards are requested, checked, and approved by the EU Commission (EU regulators).

For example, the regulation for lifts (the EU Lifts Directive) requires that the lift landing doors have adequate strength, but it does not describe the technical specifications for the level or method to verify the adequate strength. The EU Harmonised Standard, EN 81-20, provides detailed technical specifications, testing and verification method for the lift landing doors. Therefore, a lift landing door designed according to EN 81-20 is considered to be in conformity with the regulatory requirements (safety objectives) for the lift landing doors.

Distinct and separate roles of the regulation, defining safety objective without describing technical specification, versus EU harmonised standard, defining technical specification which fulfills the safety objective, has many benefits. For instance, regulations are technology neutral, and they do not need to be revised regularly due to the changes in technologies and the market greatly benefits from the stable regulation. On the other hand, Harmonised Standards are continuously evolving and reflecting the latest state of the art, innovations, and technologies, thus ensuring that the products are in accordance with the latest safety specifications.

This approach to the regulatory framework clarifies the roles and responsibilities of the regulator versus standardization organisation, while requires and encourages cooperation between them.

The work program of CEN/TC 10 includes 50 standards (see Figure 1). 33 of those standards are the EU Harmonised Standards for lifts, escalators/moving walks, lifting platforms and building hoists.

As the chairman of CEN/TC 10, I work closely with the EU Commission to define the standardization need in support of the EU regulations, formulate the criteria for acceptance of the standards by the EU Commission and ensure that the development process and the content of the standards are in line with the expectations of the Commission. I also make sure that the questions, comments, and issues raised by the EU Commission are adequately addressed, and if needed, the standards are aligned accordingly. In addition, I am a member of the EU Commission expert group which contributes to the development of the EU regulations for lifts.

Undoubtedly, experts from big companies play a key role in developing European standards at technical committees of CEN. How is the participation of small and medium enterprises (SMEs) in this process? What expertise and experience can they bring to European standards?

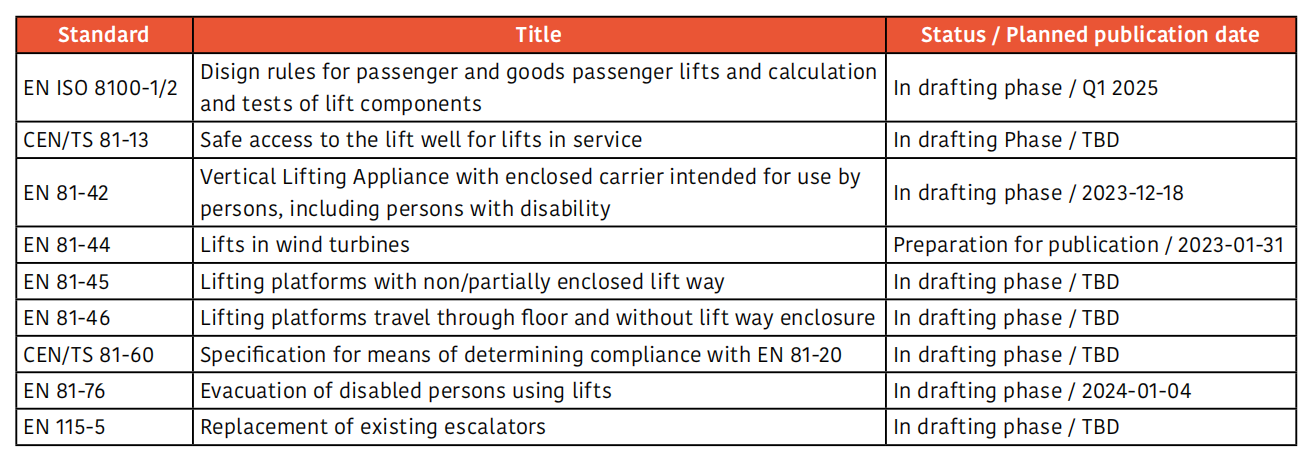

Members of the working groups and committees in CEN, the same as in ISO, are appointed by the CEN national members. Therefore, to directly participate in drafting of the standards, experts should be the members of their national standardization body. See Figure 2 for a simplified view of the structure and correlations between national and international committees and working groups.

Figure 2: Participation to CEN committees and working groups

European standardization is a transparent and inclusive process. All stakeholders and interested parties are welcome to join and to contribute to the work. SMEs are especially welcome to join. I strongly believe that technical experts of SMEs have considerable expertise and technical competence that can greatly contribute to the standardization work. For example, many SMEs are providing customized solutions in the market, which requires deep understanding of the standards and their proper application. Most SMEs are operating in a national market, thus they are very much aware of the market needs and the technical requirements for the standards, as well as need for more accurate and precise formulation of the clauses of the international standards. Therefore, SMEs’ contribution may help to ensure that the European/international standards provide relevant technical specifications, and the clauses are formulated clearly to avoid misunderstandings or misinterpretations of the content of the standards.

However, SMEs may have limited human or financial resources to participate at the European level. Therefore, SMEs are strongly encouraged to join their national standardization body. This will give them the opportunity to be fully aware of the standardization developments and the content as well as being able to provide comments during the development process and voting for acceptance of rejection of the standards.

In addition, organisations such as Small Business Standards (SBS) or European Federation for Elevator Small and Medium-sized Enterprises (EFESME), which are representing the interests of the SMEs, are actively participating in the standardization work and provide input from their respective members.

It is essential to listen to the voice of all stakeholders when developing a standard. How do consumers participate in the development of an European standard? Are their comments reflected in a standard? Please give an example.

Experts from the organisations representing consumers are also welcome to join the standardization work. Their participation may be achieved at the same structure as mentioned in Figure 2. However, the European consumer voice in standardization is the European Association for Coordinating Consumer Representation in Standardization (ANEC). ANEC enjoys strong support from the EU Commission and CEN and it is empowered to provide comments and cast a vote for accepting or rejecting the draft standards. ANEC is in liaison and in close cooperation with CEN/TC 10. ANEC experts participate in several working groups and provide their input and comments during the standardization process.

For example, ANEC has provided considerable number of requirements, comments and input related to the accessibility to lifts such as car dimensions for the wheelchair users, level of lighting inside the car or level of contrast for better visibility of the pushbuttons, etc. Those requirements have been incorporated into the EN 81-70 on accessibility to lifts for persons including persons with disability.

Why do we need so many standards? By adopting European standards, in particular EU Harmonised Standards, what benefits can it bring to lift or escalator manufacturers? How is the application of these standards in China’s lift manufacturers or foreign lift manufacturers located in China?

Development and maintenance of standards is a time-consuming and complex process. In addition, lifts and escalators are complex machinery with many aspects, such as safety, accessibility, fire, influence by external electromagnetic fields, connectivity, maintenance, replacement, etc. Continuous technological progress regularly affects one or more aspects.

CEN/TC 10 standards are made based on the modular structure. In this structure, the main safety requirements applicable to all lifts are put into the main safety standards (EN 81-20/50). Other aspects, which may not be common for all lifts are put into auxiliary/supplementary standards. For example, specific requirements for the firefighter lifts are covered by EN 81-72. Modular structure helps the users to identify the standards applicable to their specific lift design and intended use. In addition, when due to technological or regulatory changes a specific aspect of the lift, e.g. firefighting, needs to be reviewed and updated, this will affect only the supplementary standard (EN 81-72) rather than revising the main safety standards (EN 81-20/50). Therefore, the revision of the requirements for the firefighter lifts will be done faster and affects only the firefighter lifts. The same logic applies to other supplementary standards.

Use of Harmonised Standards has many benefits. As mentioned above, installers and manufacturers must comply with the regulatory requirements. But those requirements are safety objectives and do not describe the technical specifications to fulfil those objectives. Installers and manufacturers may use own technical specification to comply with the regulatory requirements, but then they must prove that their specifications provide adequate and the state-of-the-art safety for their products. This is a very complex, time consuming and costly conformity assessment procedure.

Design according to the EU Harmonised Standards is considered to be in conformity with the regulatory requirements. Therefore, the conformity assessment procedure is highly simplified, it is shorter and more cost effective.

In any case, the EU Harmonised Standards reflect the state of the art for safety and any other specifications must be evaluated against those standards. Installers and manufacturers must consider those standards even if they decide to apply their own or other specifications.

EU Harmonised Standards are adopted by many countries outside Europe and for many years. This is especially the case with EN 81-20/50, the main safety standards for lifts. Considering the extensive use of EN 81-20/50 around the world, ISO decided to adopt those standards as the identical ISO standards, ISO 8100-1/2:2019. These ISO standards are being adopted as the national standards around the world. For example, China GB/T 7588.1/2 or India IS 17900-1/2 are based on these ISO standards. It is estimated that more than 90% of the output of the lift industry is based on ISO 8100-1/2 (or EN 81-20/50), which have been adopted as national standards, identical or with small differences.

This extensive coverage of the common specification for safety (ISO 8100-1/2 or EN 81-20/50) has many advantages. It improves safety for users and workers around the world while it improves efficiency and reduces costs for manufacturing, installation, and maintenance with benefits for all stakeholders, including owners and operators for lifts.

As Chairman of CEN/TC 10 and Vice President of Codes and Standards in KONE Corporation, can you talk about the cooperation made between China and Europe in the lift and escalator industry? What is your advice for the cooperation in the future?

Cooperation between China’s SAC/TC 196 and CEN/TC 10 began in mid-1990s with exchanging technical question and answers. That cooperation evolved into a cooperation agreement in 2005. Two TCs have been exchanging work programs and draft of the standards for comments and input as well as having regular technical exchange meetings with participation of many Chinese and European experts.

The cooperation was highly intensified during the development of EN 81-20/50 standards. SAC/TC 196 provided many comments and proposals for those standards and the two TCs had many meetings to discuss the draft of those standards. I strongly believe that these exchanges and input from SAC/TC 196 brought huge improvements to the EN 81-20/50 standards to the level that ISO decided to adopt those standards as global ISO standards. This is a unique achievement for these two TCs and the industry in general.

In 2019, the cooperation moved to a higher level by forming a joint working group. This joint working group is providing commonly agreed proposals for the safety requirements for standards as an input to ISO as well as European and Chinese standards.

I truly believe that the cooperation has been mutually beneficial for China and Europe as well as the rest of the world in the form of ISO standards.

We have also achieved strong alignment of the technical requirements. Currently, European and Chinese standards are almost identical. This alignment is not only crucial for facilitating smoother trade between the two parties, but also essential for the trade worldwide. We need to make all the efforts to maintain this alignment.